CIRCLE IMPACT REPORT 2023

PRODUIT.

L’ÉCO-CONCEPTION, NOTRE PRIORITÉ

Circularité, durabilité, cycle de vie, éco-design, éco-conception… Depuis la création de Circle ces enjeux sont au coeur de nos décisions. Dans chacune de nos créations, le design, le choix des matériaux et l’optimisation de la fin de vie sont pensés pour répondre aux grands principes de l’éco-design et plus largement de l’éco-conception. Qu’est ce que l’éco-design ? Le processus d’eco-design est un processus qui prend en compte les aspects environnementaux dès la conception du produit et lors de toutes les étapes de son cycle de vie, afin de créer un produit dont l'impact sur l'environnement est le plus faible possible.

POUR CONCEVOIR UN PRODUIT EN TENANT RÉELLEMENT COMPTE DE SON IMPACT ENVIRONNEMENTAL, IL EST NÉCESSAIRE DE LE CONSIDÉRER DÈS LA PHASE DE CONCEPTION DU PROJET.

Comment se passe ce processus d’éco-conception ? Un triple objectif, circularité, performance et désirabilité !

MOINS MAIS MIEUX

Un design minimaliste pour que chaque matériau apporte un bénéfice réel à la fois technique et environnemental. Mais aussi, la volonté de proposer un design qui met en valeur ces matériaux naturels et qui permet à chaque matière de pouvoir être identifiée et séparée en fin de vie. Nous cherchons toujours à maximiser l'utilisation de nos matières pour plusieurs usages pour minimiser le nombre de matières totales utilisées. Nos brassières sont par exemple doublées avec les matières adaptées de nos t-shirts Iconic.

CHOIX DES MATIÈRES PREMIÈRES

Privilégier l’utilisation de matériaux issus de ressources naturelles ou recyclées. Dès la conception du produit, nous sélectionnons des matériaux à faible impact environnemental. L’objectif: répondre à un cahier des charges exigeant en termes de performance, de qualité et d’éthique. Pour chaque matière, nous analysons et traçons la provenance de chaque fils, vérifions les certifications pour s’assurer que cela respecte notre cahier des charges. Nous créons aussi très souvent des matières car il n’existe pas de solutions suffisamment locales, naturelles ou recyclées et performantes sur le marché. C’est un long processus de +18 mois, nous ne faisons aucune concession sur la qualité et la durabilité de nos matières.

LE RECYCLAGE AVANT TOUT

Imaginer ce que deviendra le produit en fin de vie et non pas seulement à quoi il ressemblera au moment de la vente. C’est la philosophie dans laquelle nous nous plaçons dans la création de chaque produit. Anticiper la durabilité et la fin de vie du produit dès les premières étapes de sa conception afin de garantir un plan de fin de vie à faible impact est essentiel. Nous travaillons donc avec plusieurs partenaires avec qui nous testons et analysons chaque produit pour tester et garantir la durabilité au moment du développement. Enfin, les produits les plus éco-responsables sont ceux qui durent le plus longtemps possible. Nous proposons donc un service de réparation pour allonger la durée de vie de nos vêtements.

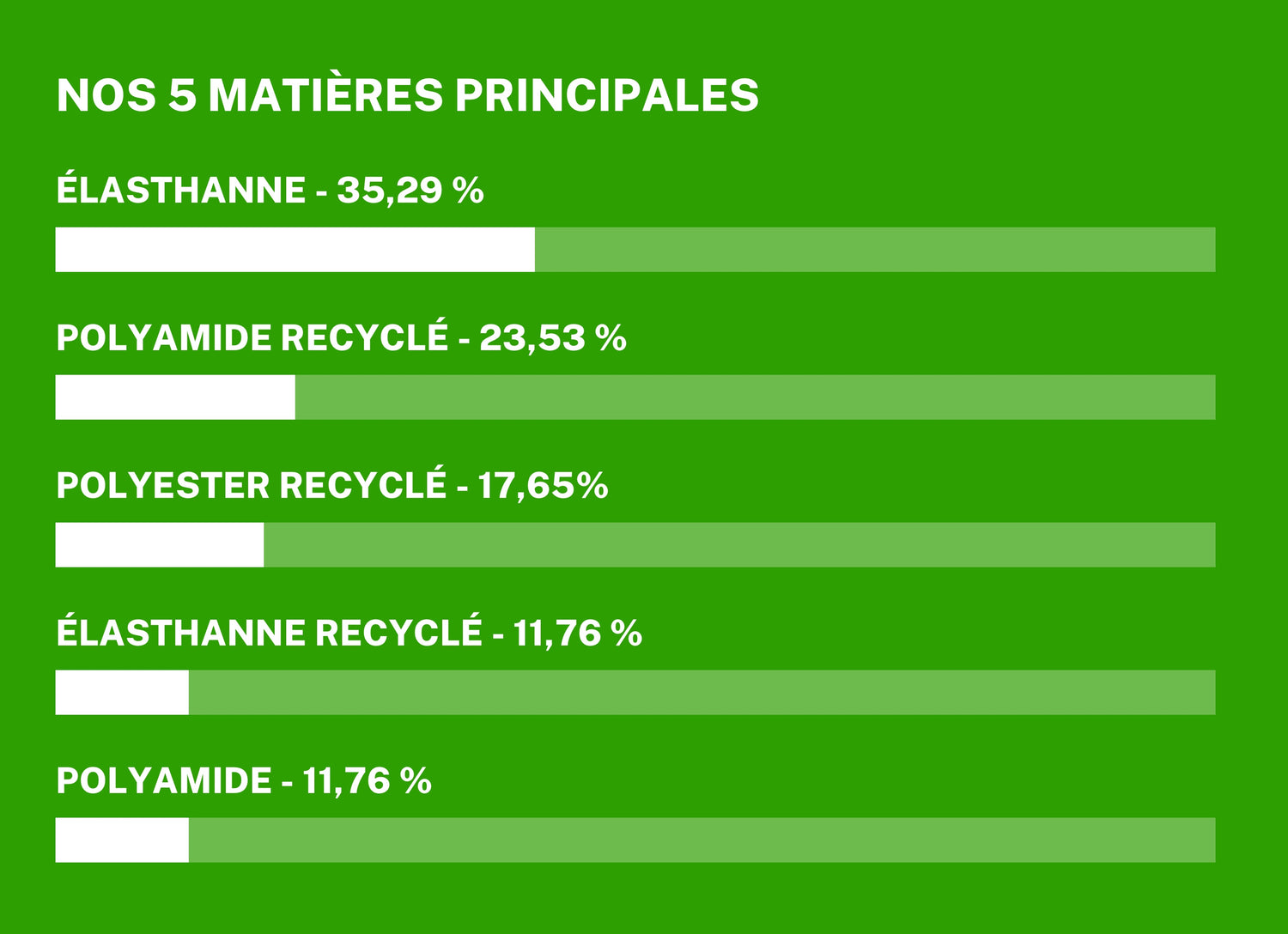

NOS MATIÈRES

POLYAMIDE RECYCLÉ Q-NOVA®

Le polyamide recyclé est un filament synthétique recyclé, issu à 100% des déchets nylon pré-consommation collectés et transformés directement dans les usines de fabrication de fil en Italie.

Le fil et la teinture sont certifiés Oeko tex Standard 100 / Reach / GRS / LCA de ICEA.

Impact environnemental - Chiffres en comparaison avec un polyamide vierge (non recyclé)

- - 80% d'émissions de CO2

- - 90% de consommation d'eau

- Procédé de transformation mécanique, pas de produits chimiques nocifs pour l'homme et l'environnement

Actions de notre fournisseur de tissu qui utilise le Qnova®

- Économies d'environ 400 tonnes de C02/an.

- Un système de gestion des ressources en eau en interne permet de maintenir la consommation d'eau à des niveaux optimaux

- Réutilise 98% de sa production

POLYESTER RECYCLÉ NEWLIFE™

Le polyester recyclé est un filament synthétique recyclé. Il provient à 100% de bouteilles de plastiques transparentes post-consommation, collectées dans les bennes à ordure à 40 km autour de Turin puis recyclées mécaniquement et extrudées à Biella en Italie. Le fil et la teinture sont certifiés Oeko tex Standard 100 / Reach / GRS / LCA de ICEA.

Impact environnemental - Chiffres en comparaison avec un polyester vierge (non recyclé)

- 25 tonnes récoltées/h

- - 60% de consommation d'énergie

- - 32% d'émissions de CO2

- - 94% de consommation d'eau

- Procédé de transformation mécanique, pas de produits chimiques nocifs pour l'homme et l'environnement

Action de notre fournisseur de tissu qui utilise le Newlife™

- Participe aux traitement des eaux de la ville avec la station d'eau de Bourgoin-Jallieu

ELASTHANNE RECYCLÉ ROICA™ ECO SMART

L’élasthanne recyclé est un filament synthétique recyclé, issu à 58% des déchets nylon pré-consommateurs collectés et transformés en Allemagne et 42% de nylon 6.6 régénéré en Allemagne. Le fil et la teinture sont certifiés : Cradle to Cradle Gold Level / Oeko Tex Standard 100 / Reach / GRS.

Impact environnemental - Chiffres en comparaison avec un élasthanne vierge (non recyclé)

- - 35 % d'émissions de CO2

- - 75% d'énergie de chauffe

- - 64% d'utilisation de la matière première brute en production

- + de 50% de récupération des déchets de polymères en polymérisation

- + de 90% de récupération du fil pendant le filage

- Procédé de transformation mécanique, pas de produits chimiques nocifs pour l'homme et l'environnement

Actions de notre fournisseur de tissu qui utilise le Roica™ Eco Smart

- Réduction de la consommation d'eau de 98%

- Réduction d'énergie d'environ 45% : 460 KW de panneaux photovoltaïques ajoutés à des systèmes d'énergie solaire.

Ces pratiques durables s'inscrivent dans notre engagement à réduire notre empreinte écologique et à promouvoir une chaîne d'approvisionnement plus respectueuse de l'environnement.

0 %

Fabriqué en Europe

L’intégralité de nos produits sont fabriqués localement par nos partenaires en Europe.

0 %

De matières recyclées

En moyenne pour nos produits faits à partir de matières recyclées.

0 %

De matières d'origine naturelle

En moyenne pour nos produits faits à partir de matières d’origine naturelles.

0 %

Recyclables et/ou biodégradables

L’intégralité de nos produits sont recyclables et/ou biodégradables en fin de vie.

0 KM

Parcourus en moyenne lors des différentes étapes de fabrication

En moyenne, nos vêtements parcourent 6 fois moins de kilomètres avant d'arriver chez vous, contre 45 000 kms en moyenne pour des vêtements de sport fabriqués en Asie.

SUPERNATURAL RUNNER

Performante, éthique et responsable = 0 compromis.

Nous ne trouvions pas de chaussures de running à la fois circulaire, performante et esthétique pour nous emmener là où on voulait aller. Alors on l’a créée. Avec la SuperNatural Runner notre ambition a été de créer la chaussure de running la plus respectueuse de l’environnement à l’échelle mondiale, marquant ainsi une avancée significative dans le secteur. Il s’agit de la première chaussure de running performante, respectant les principes de l’économie circulaire et pour la première fois fabriquée en Europe. Grâce à l’utilisation de matériaux naturels ou bio-sourcés ainsi qu’à des méthodes de construction novatrices, la SuperNatural Runner réduit de manière significative son empreinte environnementale.

CIRCULAIRE

Des matériaux naturels et biosourcés hautement recyclables ou biodégradables, avec une construction permettant un désassemblage facilité de ces différents matériaux en fin de vie. Le haut de la chaussure est biodégradable et la semelle est recyclable tout en permettant de fabriquer les futurs semelles à partir des existantes.

PERFORMANCE

1 millions de foulées analysées, 290 grammes de performance. La SuperNatural Runner a été co-développée avec +50 athlètes et + 5000 kilomètres ont été réalisés pour analyser chaque impact et offrir une sensation unique sur toutes les distances.

LOCALE

Fabriquée entièrement en Europe avec une chaîne d'approvisionnement de haute qualité, éthique et locale.

DES PARTENARIATS DURABLES

Un écosystème de partenaires et d'ambassadeurs pour créer, ensemble, la chaussure de running du futur.

Notre équipe technique interne a travaillé en collaboration sur le développement de la partie supérieure de la chaussure, exploitant les avantages de performance de la laine Mérinos - telles que la respirabilité et la résistance aux odeurs - pour pousser la nature innovante de la fibre pour une chaussure de course haute performance." John Roberts - Directeur Général de The Woolmark Company -

"L'industrie des chaussures de running est dominée par les développements à base de pétrole. Circle Sportswear a relevé le défi avec la SuperNatural Runner en offrant une alternative responsable sans compromettre les performances. La combinaison du filament TENCEL™ Lyocell de Lenzing et de la laine de Woolmark avec la technologie ProWeave® de Coats Footwear ouvre de nouvelles possibilités pour promouvoir le développement de chaussures de running sans matériaux synthétiques" Lenzing AG, Nicole Schram, Directrice du Développement Commercial Mondial

CIRCLE IMPACT REPORT 2023

CIRCULARPERF LAB

NOS NOUVELLES MATIÈRES

Notre engagement continue envers l'innovation est de rendre la circularité accessible à tous. Notre équipe technique développe de nouveaux matériaux plus légers, résistants, respirants et recyclés pour nos produits. En collaboration avec des partenaires de confiance, nous repensons notre production pour créer des vêtements de haute qualité respectueux de l'environnement, sans sacrifier le style, le confort et les performances.

NANOTECH™

Nous nous sommes associés avec l’IMT Mines Albi dans le cadre du programme de recherche “Nanotech” afin d’analyser le relargage de micro/ et ou nanoparticules de plastiques de nos vêtements au cours d’un cycle de lavage. L’objectif était d’évaluer l’impact de nos produits et de trouver des solutions contre le relargage des microplastiques lors du cycle de lavage.

PLNT-FOAM™

L’INNOVATION AU SERVICE DE LA CIRCULARITÉ

Pour la semelle de la SuperNatural Runner, nous avons développé une nouvelle mousse innovante PLANTFOAMTM crée partiellement à partir de graines de ricin en partenariat avec Arkema.

NANOTECH™

Nous nous sommes associés avec l’IMT Mines Albi dans le cadre du programme de recherche “Nanotech” pour analyser le relargage de micro et/ou nanoparticules de plastiques de nos vêtements au cours d’un cycle d’utilisation et de lavage. L’objectif est d’évaluer l’impact de nos produits dans leur cycle de vie utilisateurs et de lutter et trouver des solutions contre le relargage.

Cette problématique a été exposée au laboratoire RAPSODEE de l’IMT Mines Albi et à l’Institut Français du Textile et de l’Habillement (IFTH) et nous avons pu évaluer le relargage de particules sur trois références de matière :

- Tissu 100% PES recyclé utilisé pour nos shorts One For All

- Maille 49%PES-43%PA utilisé pour nos t-shirts Agility

- 65% polyamide recyclé - 25% Elasthanne utilisé pour tous nos leggings et shorts Get In Shape, Get Shorty ou Hit The Road.

Contexte analyse

Réalisation de mesures granulométriques par diffraction laser pour mesurer la taille de particules et la distribution granulométrique des particules. Cela permet la caractérisation de particules de 10 nm à 3500 μm.

Tests lavage

- Réf 1 : Tissu 100% PES rec + slip

Mousse en surface / Faible variation d’obscuration : objets en très faible quantité / Les tailles ne sont pas exploitables, la microscopie vient toutefois confirmer la présence de fibres et autres agglomérats issus du textile analysé.

- Réf 2 : Maille 49% PES rec 43% PA rec - EA rec

Mousse en surface + Eau trouble / Présence d’objets en faible quantité après 2ème prélèvement / Éléments diamètres les plus fins : 1 à 2 microns / Éléments diamètres moyen : entre 58,3 et 60,9 microns.

- Réf 3 : Maille 65% PA rec - 25% EA

Eau trouble / Présence d’objets en faible quantité après 2ème prélèvement / Éléments diamètres les plus fins : 15 microns / Éléments diamètres moyen : entre 72 microns.

Les Résultats et une hypothèse.

Le relargage est avéré et en très faible quantité, 5x plus bas que des produits fabriqués à partir de fibres synthétiques traditionnelles notamment car l’ensemble des solvants et produits utilisés dans la fabrication sont écologiques. Une hypothèse : plus le taux de matières est recyclé, plus le relargage est faible.

CIRCLE IMPACT REPORT 2023

TRAÇABILITÉ ET TRANSPARENCE

Nous assurons une traçabilité et une transparence totale sur notre chaîne d'approvisionnemenT.

Zoé Loevenbruck, responsable production - Circle Sportswear

L’article 13 de la loi AGEC prévoit de rendre obligatoire l’affichage de certaines caractéristiques environnementales des produits afin d’informer le public d’ici 2026. Bien que cette loi ne concerne pas encore les petites entreprises, notre engagement envers la durabilité est au coeur de tout ce que nous faisons. En choisissant de collaborer avec Fairly Made pour réaliser des Analyses du Cycle de Vie sur nos vêtements (une méthode d’évaluation visant à quantifier les impacts environnementaux d’un produit ou d’un service, nous avons analysé l’ensemble de nos différentes matières afin d’évaluer chacun de nos produits et ainsi garantir une traçabilité complète, vérifiée par un tiers. Grâce à cette analyse, nous offrons à notre communauté une transparence totale sur notre chaîne d’approvisionnement et l’impact de celle-ci.

0 %

De nos matières analysées

Avec sa méthode d’AVC, Fairly Made a analysé 100% des matières que nous utilisons dans nos différentes collections.

0

Traçabilité

Note attribuée par Fairly Made après analyse de notre chaîne de production.

0

Recyclabilité

Note attribuée par Fairly Made après analyse de la capacité de recyclage de nos produits.

0

Éco-score

L’éco-score ou PEF (Product Environmental Footprint) attribué par Fairly Made qui vise à évaluer les impacts environnementaux de nos produits, et ce, tout au long de leur cycle de vie.

TRANSPARENCE ET TRAÇABILITÉ

Pour vous et pour nous !

Depuis la création de Circle Sportswear, nous avons 100% de traçabilité sur tous nos produits. Autrement dit, nous pouvons reconstituer tout le chemin parcouru depuis la matière première jusqu’à la confection finale du vêtement en passant par la filature, le tissage et sa teinture.

Nous avons fait le choix de ne pas apposer d’étiquettes sur les vêtements Circle mais un QR code. C’est un passeport qui présente chaque étape de fabrication et qui partage les différentes options lors de la fin de vie du produit.

La collaboration avec Fairly Made, véritable contrôle externe, vient définitivement certifier cette transparence avec une note attribuée de 5/5 en traçabilité. Le choix de nos fournisseurs, leur proximité et les certifications qu’ils possèdent nous permet d’avoir une vision claire de la provenance de tous les éléments qui composent nos produits.

CIRCLE IMPACT REPORT 2023

CERTIFICATIONS

Dans notre quête de pratiques transparentes et durables, les certifications de nos partenaires jouent un rôle central pour garantir l'intégrité de chaque étape de la production de nos vêtements : la culture et transformation de la matière première en fil, le processus de teinture ou encore la fabrication. Ces certifications couvrent différents aspects de la responsabilité environnementale et sociale, façonnant ainsi une vue holistique de nos opérations.

Oeko-Tex Standard 100 - Cette certification assure que le tissu final, les teintures et les finitions sont exempts de substances nocives pour notre santé. Elle prend en compte une large gamme de substances réglementées et non réglementées, notamment les pesticides, les colorants cancérigènes et les métaux lourds.

GRS - Global Recycled Standard - La certification GRS mesure et certifie le pourcentage de matériaux recyclés dans le tissu (un minimum de 50 %) ainsi que le respect de divers critères environnementaux et sociaux. Les entreprises doivent respecter et surveiller les exigences légales concernant la consommation d'eau, la consommation d'énergie et la production de gaz à effet de serre. Il est interdit de brûler des déchets sur place, et les réglementations légales sur les eaux usées doivent être suivies, avec un système dédié de traitement des eaux usées avant leur rejet dans les cours d'eau. GRS certifie également l'interdiction du travail forcé et du travail des enfants, de la discrimination, du harcèlement et des abus, tout en veillant à la santé et à la sécurité des travailleurs, aux salaires, aux horaires de travail et à divers aspects sociaux.

Cradle to Cradle Gold Level - Avec cette certification, les produits sont évalués pour leur performance environnementale et sociale dans cinq catégories critiques de durabilité : la santé, la réutilisation des matériaux, la gestion des énergies renouvelables et de la gestion du carbone, la gestion de l'eau et l'équité sociale. La catégorie santé garantit l’absence de substances nocives dans la fabrication des produits. La réutilisation des matériaux vise à éliminer le concept de déchet en contribuant à ce que les produits restent dans des cycles perpétuels d'utilisation et de réutilisation. La catégorie des énergies renouvelables garantit une fabrication à l'aide de sources d'énergie renouvelable. Enfin, la gestion de l'eau vise à améliorer la protection des bassins hydrographiques. L'objectif de ces catégories est de certifier l’ensemble des opérations nécessaires à la fabrication d’un produit.

Bluesign - Cette certification garantit l'absence de substances toxiques pour les humains et l'environnement, l'optimisation des ressources et la gestion des déchets. Elle répond à des exigences environnementales en mettant l'accent sur l'efficacité des ressources dans la production et la fabrication, le traitement des déchets, la consommation d'eau contrôlée, l'utilisation de produits chimiques et les émissions de CO2. En ce qui concerne les normes sociales, Bluesign certifie l'interdiction du travail forcé et du travail des enfants, la santé et la sécurité des travailleurs, ainsi que l'égalité des sexes.

Reach - est une norme qui contrôle l’utilisation des substances chimiques dans l’industrie européenne. L’objectif est de recenser, d’évaluer et de contrôler les substances chimiques fabriquées, importées et mises sur le marché européen.

UN PACKAGING RESPONSABLE

Depuis la création de Circle Sportswear, nous nous sommes engagés dans la recherche de solutions à faible impact carbone et pas uniquement sur nos produits. Les packagings Circle répondent à nos exigences de qualité et durabilité, tout en réduisant au maximum leur impact.

FAIBLE IMPACT CARBONE ET RECYCLABILITÉ

Nous croyons fermement en l'utilisation de matériaux recyclés pour réduire notre empreinte environnementale. Nos emballages sont entièrement recyclables, conçus en Europe et fabriqués à partir de craft, une matière naturelle. Cette approche soigneusement choisie permet de minimiser notre impact sur l'environnement tout en garantissant des emballages de la plus haute qualité.

UN PACKAGING LOCAL

Notre engagement envers des pratiques respectueuses de l'environnement se reflète également dans notre choix de partenaires et une provenance locale. Nous privilégions le Portugal et la France pour nos emballages, réduisant ainsi considérablement notre empreinte carbone. Nos partenaires de confiance, tels que Cadica en Italie et Open Eyes en Pologne, partagent notre engagement pour des solutions durables.

UN PACKAGING DOUBLE USAGE

Nous pensons que chaque emballage est une opportunité de partager nos valeurs et notre engagement en faveur de l'environnement. C'est pourquoi nous concevons nos emballages pour un double usage, allant au-delà de leur simple fonction. Chaque emballage est un support de communication, transmettant un message qui reflète nos engagements en matière de durabilité.

En adhérant à ces critères, nous sommes convaincus que nos emballages contribueront de manière significative à notre mission de durabilité, tout en offrant une expérience de marque significative pour nos clients.

LE PRODUIT LE PLUS ÉCO-RESPONSABLE EST CELUI QUI DURE LE PLUS LONGTEMPS POSSIBLE.

CIRCLE IMPACT REPORT 2023

BACK TO THE FUTURE

NOTRE ENGAGEMENT POUR LA CIRCULARITÉ

La fin de vie du produit est un des leviers les plus importants de la circularité. Quand on sait que chaque année l’équivalent du poids de 13 Tour Eiffel termine à la poubelle, il fallait trouver une solution. Notre objectif est de minimiser la création de déchets de surconsommation. Grâce à notre programme Back To The Future, trouvez la meilleure solution selon votre situation : personnalisation, réparation, ou recyclage !

Comment s’articule ce programme ? Que faisons-nous des vêtements, une fois récupérés ?

Dès réception de nos produits, notre équipe technique procède à une évaluation du produit pour déterminer la meilleure alternative. Trois solutions distinctes sont offertes à nos clients pour répondre aux différentes étapes de la vie de nos produits.

LA PERSONNALISATION

Créer un produit, un look un style unique tout en rallongeant la vie de vos produits grâce aux badges Circle.

LA RÉPARATION

Notre ambition, faire que nos produits durent le plus longtemps possible, pour vous et pour la planète. Si un produit est endommagé mais réparable, nous nous engageons à le restaurer pour prolonger sa durée de vie. Nous avons établi un partenariat avec Tilli Paris, un réseau de 500 artisans experts, pour mettre en place un processus de réparation complet pour l'ensemble de nos produits. Nous avons testé et collaborons avec des couturiers soigneusement sélectionnés et tous équipés de machines techniques adaptés à la réparation de nos produits performants.

Comment ça fonctionne concrètement ?

- Pour faire une demande, rdv sur https://circlesportswear.com/pages/reparation-et-entretien

- Un questionnaire est disponible pour récolter les besoins de chacun

- Nous proposons la meilleure solution pour le produit. Si une réparation est nécessaire, nous prenons en charge l’ensemble du processus pour offrir une garantie à vie sur tous les produits Circle.

LE RECYCLAGE

Le recyclage étant un processus énergivore, il n’arrivera qu'en solution finale, si le vêtement ne peut ni être réparé, ni upcyclé.

Le recyclage, comment ça marche?

Chaque produit est testé pour en connaître le potentiel recyclable. Si la matière n’a pas perdu de sa résistance et de sa performance, notre partenaire la transforme en fil pour fabriquer de nouveaux tissus. Au contraire, si celle-ci ne peut être ré-utilisée, de nouveaux objets ou accessoires seront fabriqués.

Suivez nos aventures

Actualités, événements, guides & conseils, innovations environnementales, co-design

et circularité. En vous inscrivant, rejoignez le collectif Circle. La newsletter est envoyée

2 à 4 fois par mois, pas plus. On s'y engage.